Are you looking to understand gate valves and how they function in various applications? Gate valves are essential components in many industrial and residential systems, but their complexity can be daunting. This article will demystify gate valves, covering their components, working principles,types of typical gate valve, and practical applications. By the end, you’ll be equipped to make informed decisions about selecting the right gate valve for your needs.

What is a Gate Valve?

A gate valve is a type of valve used to control the flow of fluids in a pipeline. Unlike other valve types, gate valves operate by raising or lowering a gate within the valve body. This design allows for minimal flow resistance when the valve is fully open, ensuring that the flow path is unobstructed. This feature makes gate valves ideal for applications where a straight line flow is essential.

In addition, gate valves can be equipped with a non-rising stem, which means the stem does not extend above the valve body during operation. This is particularly advantageous in situations where space is limited. Gate valves are commonly used in water supply systems, chemical processing, and oil and gas industries, where reliable and efficient flow control is necessary.

Gate valves are versatile components that play a vital role in ensuring the safe and effective management of fluids across numerous industries, including, fire protection, water supply systems, chemical processing, oil and gas Industry, HVAC Systems.

Advantages and Disadvantages of Gate Valves

| Advantages | Disadvantages |

|---|---|

| Minimal flow resistance when fully open | Not suitable for throttling or flow regulation |

| Provides a straight-line flow path | Slow operation compared to other valve types |

| Excellent sealing capability when fully closed | Requires more space for installation (especially rising stems) |

| Durable and reliable for on/off control | Potential for erosion if operated in partially open position |

| Simple design with fewer moving parts | Maintenance can be complex if not easily accessible |

| Cost-effective for many applications | Can be prone to thermal binding in high-pressure applications |

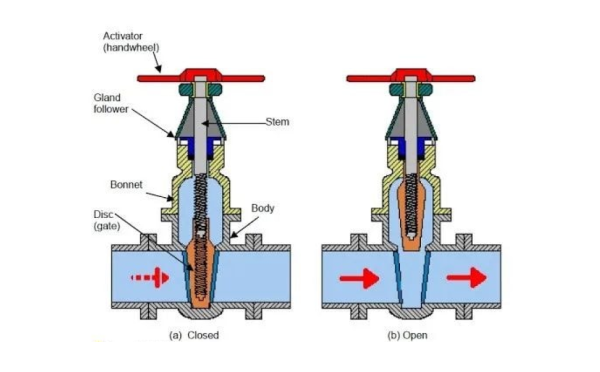

How Does a Gate Valve Work?

Gate valves operate using a simple mechanism to control fluid flow. When the actuator (often a handwheel) is turned, the threaded stem moves up or down, raising or lowering the gate. This action either allows or blocks the flow of fluid through the pipeline.

The valve is fully opened when the gate is raised completely, providing minimal resistance to fluid flow and allowing for optimal flow rate. Conversely, when the gate is lowered, the fluid flow is completely obstructed, resulting in a closed valve position.

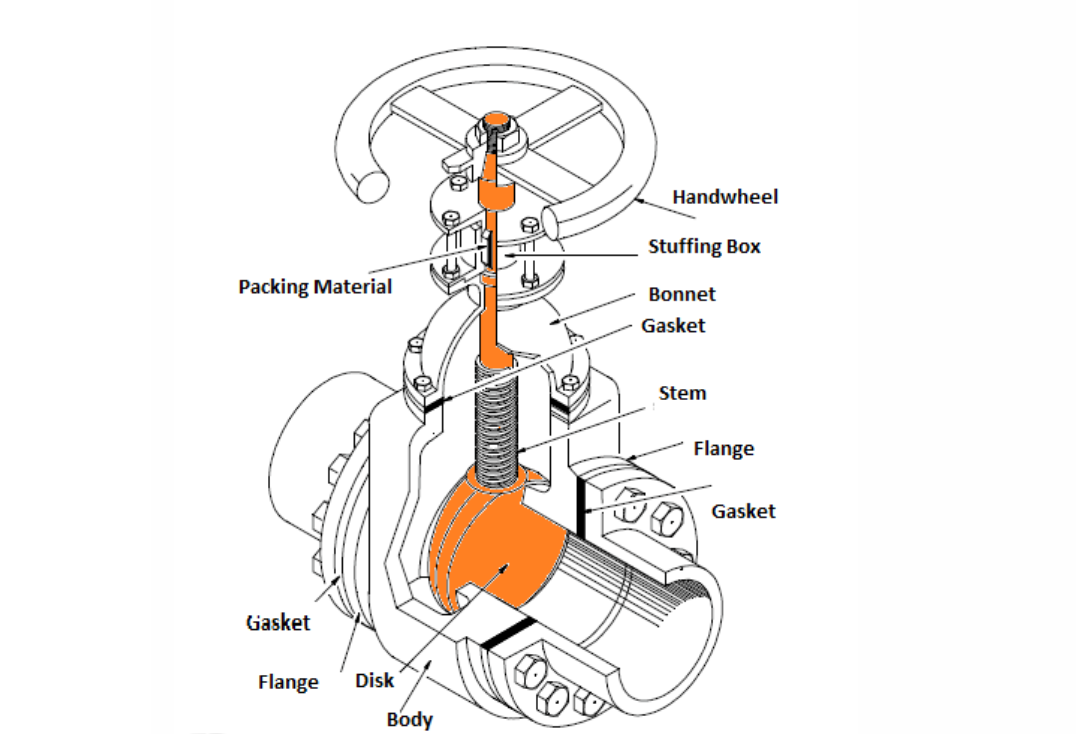

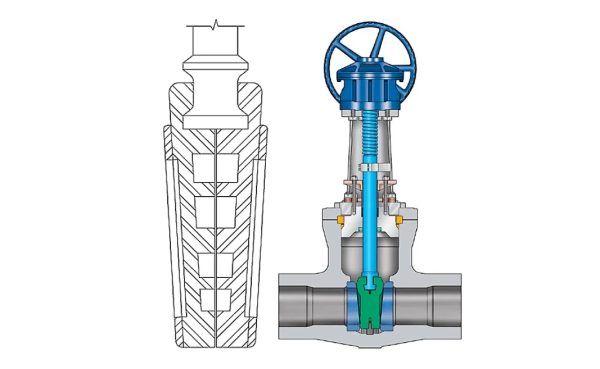

Parts of Gate Valves

- Body: The body is the main component of gate valves, holding all other parts together. It is typically connected to the pipeline via flanges and gaskets, serving as the pressure boundary of the valve.

- Bonnet: The bonnet acts as the second pressure boundary and is connected to the body by bolts or flanges. It provides access to the internal components for maintenance.

- Stem: The valve stem connects the actuator (such as a handwheel) to the disc (or gate). It is responsible for opening and closing the disc, allowing fluid to flow or blocking it. There are two types of stems: rising stems and non-rising stems. A rising stem moves vertically as the valve opens, requiring additional vertical space, while a non-rising stem does not extend above the valve body.

- Disk: The disk, or gate, is typically wedge-shaped and directly controls the flow of fluid. It fits tightly against the seat to create a seal when the valve is closed. The design of the gate faces, often parallel, ensures a better seal and prevents leakage.

- Seat: The seat is the surface against which the disk seals when the valve is closed. The arrangement of the seat and disk is critical for the valve’s performance, especially regarding maintaining an unobstructed flow path during operation.

- Stuffing Box: The stuffing box contains packing material that seals the stem and prevents leakage. It ensures that the valve maintains its integrity under pressure.

- Packing Material: This material is used in the stuffing box to provide a seal around the stem, preventing fluid from leaking out of the valve.

- Gasket: Gaskets create a seal between the body and bonnet, ensuring that no fluid escapes from the connection points.

- Flange: Flanges are used to connect the valve body to the pipeline, providing a secure and leak-proof joint.

Typical Gate Valve Types

Each of these gate valve types has its own specific advantages and applications, allowing for effective fluid control in various industrial settings.

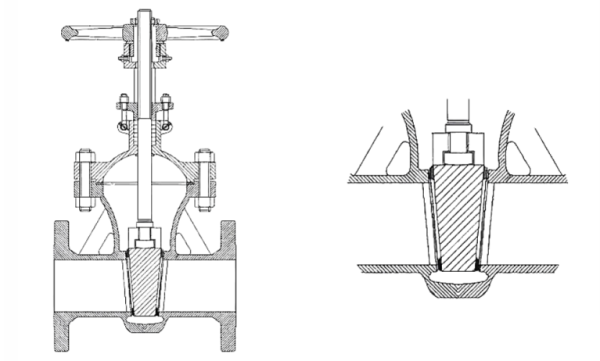

Solid Wedge Gate Valve

This is a very popular type of gate valve suitable for a wide range of materials. It utilizes a wedge-shaped disc that is installed on the valve seat. Solid wedge gate valves are effective in medium-pressure conditions but are not recommended for high-pressure applications due to the risk of jamming, which can lead to leaks. Additionally, thermal expansion can cause the seat to become stuck, a phenomenon known as “thermal binding.”

Parallel Disk or Split Gate Valve

This type overcomes the thermal binding issue by allowing movement. It features two discs that are held together with a spring mechanism. Parallel disk gate valves are suitable for low-pressure and medium-pressure applications, providing flexibility and reliability.

Flexible Wedge Gate Valve

A flexible wedge gate valve has a small notch cut into the disc that fits with the valve seat. This design prevents leakage between the seat and the disc, making it particularly useful for steam applications, where pressure and temperature fluctuations can be significant.

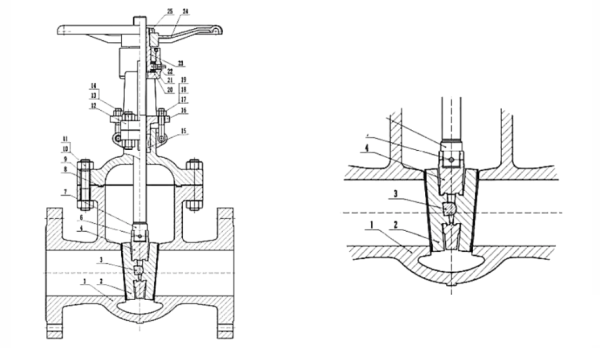

Non-Rising and Rising Stem Gate Valve

- Rising Stem Gate Valve: In this design, the stem rises vertically when the valve is opened, and it lowers when the valve is closed. This provides a clear visual indication of the valve position.

- Non-Rising Stem Gate Valve: In contrast, the stem does not move vertically, making it suitable for applications with limited vertical space. This type is ideal for installations where height clearance is a concern.

In addition to traditional designs, gate valves can also include specialized types, such as the knife gate valve, pvc gate valve, and water gate valve. This variant is particularly effective for handling slurries and viscous fluids, as its sharp blade can cut through materials, making it suitable for sewage and wastewater applications.

Frequently Asked Question

What is the gate valve symbol?

In engineering diagrams and schematics, the symbol for a gate valve is typically represented as a simple line with a vertical line segment intersecting it.

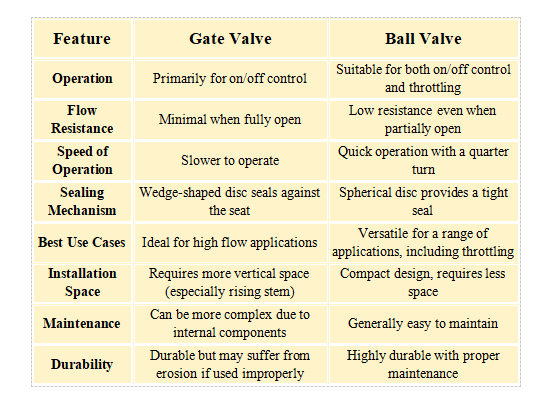

Gate valve vs. ball valve?

The differences between gate valve and ball valve are as below.

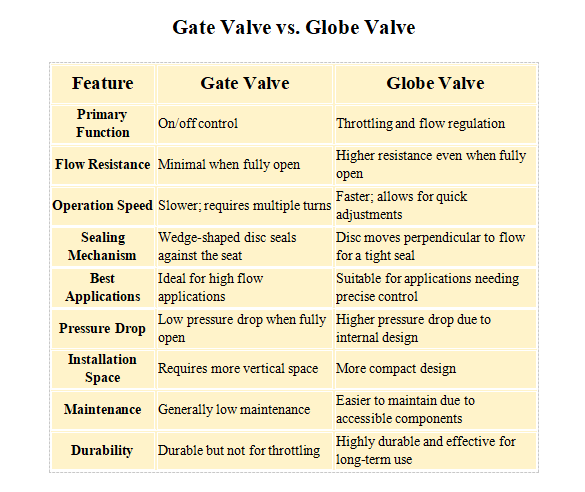

Gate valve versus globe valve?

Conclusion

Having a good grasp of valves is important for anyone working with fluid systems, whether in industrial settings or at home. This article has explored the key aspects of gate valves, including their components, how they work, and the different types available. With this knowledge, you’ll be better equipped to choose the right gate valve for your specific needs.

If you’re unsure about selecting the right gate valve for your industrial application, don’t hesitate to reach out to Amber. We’re here to offer expert advice and provide you with top-quality gate valves tailored to your various requirements.