Pressure Relief Valves (PRV) are essential safety devices widely used in industrial applications to prevent over pressure conditions. Understanding their function and design is crucial, especially for operations that rely on pressurized systems. This article provides comprehensive insights into PRV, including their working principles, types, applications, and guidance on selecting suitable valves.

It’s also important to distinguish between Pressure Relief Valves and Safety Relief Valves, as they serve different purposes in safety management. By the end of this article, you’ll have a solid foundation of knowledge about PRVs, empowering you to make informed decisions regarding their use and maintenance.

What is a Pressure Relief Valve (PRV)?

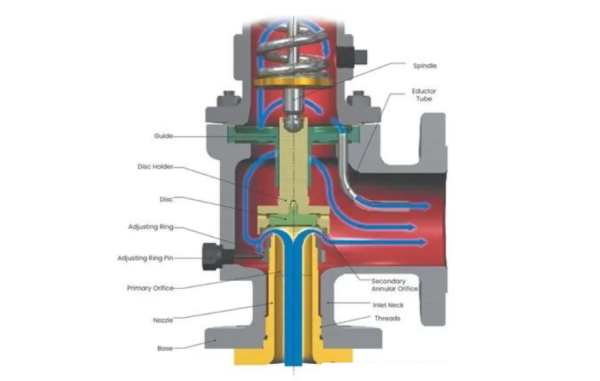

Pressure Relief Valves (PRV) are essential components that manage and maintain system pressure within safe limits. Primarily, they divert flow when the inlet pressure reaches a predetermined set point, ensuring downstream pressure remains stable. The most common is the direct-acting valve, which operates based on spring compression.

In a typical PRV, a spring acts against a diaphragm or piston to keep the valve closed during normal operation. When the inlet pressure exceeds the set point determined by the spring’s tension, the increased pressure compresses the spring further, allowing the valve to open and relieve excess pressure. This release can occur through an outlet port or directly to the atmosphere, depending on the valve’s design.

The valve seat is crucial, as it provides the sealing surface that prevents flow when the valve is closed. A well-designed seat ensures proper function, preventing leaks and maintaining system integrity.

In pumped systems, these valves are often referred to as divert valves. When pressure exceeds the set point, the divert valve redirects fluid back to the reservoir. If flow demand decreases and pressure drops below the set point, the valve closes, allowing pressure to build up again.

The core components of a PRV include:

| Valve Body | Houses internal components and connects to the pipeline, ensuring proper flow direction. |

| Seat | The sealing surface that prevents flow when the system operates below the set pressure. |

| Poppet or Disk | The movable element that opens to relieve pressure when the inlet pressure exceeds the preset threshold. |

| Spring | Provides the force that keeps the valve closed until the preset pressure is reached, ensuring effective operation under varying conditions. |

Understanding these components is vital for the efficient operation of PRVs, which play a key role in complying with safety regulations like the Pressure Equipment Directive in Europe. By effectively managing pressure, PRVs help prevent accidents and ensure the safety of pressure systems.

What is the Function of a Pressure Relief Valve?

Then what does a pressure relief valve do? A pressure relief valve (PRV) serves a critical safety function in pressurized systems by preventing overpressure conditions. Here’s a breakdown of its primary functions:

-

- Pressure Regulation: PRVs maintain system pressure within safe limits by releasing excess pressure when it exceeds a predetermined set point.

-

- Flow Control: When the internal pressure rises beyond the set threshold, the valve opens to allow fluid (gas or liquid) to escape, thus reducing the pressure in the system.

-

- Protection Against System Failure: By relieving excess pressure, PRVs help prevent potential equipment damage, leaks, or catastrophic failures that could arise from overpressure conditions.

-

- Automatic Operation: PRVs automatically close once the system pressure returns to a safe level, ensuring continuous protection without manual intervention.

-

- Safety Assurance: They are crucial components in various industries, including oil and gas, chemical processing, and HVAC systems, where pressure management is essential for safe operation.

How Does a Pressure Relief Valve Work?

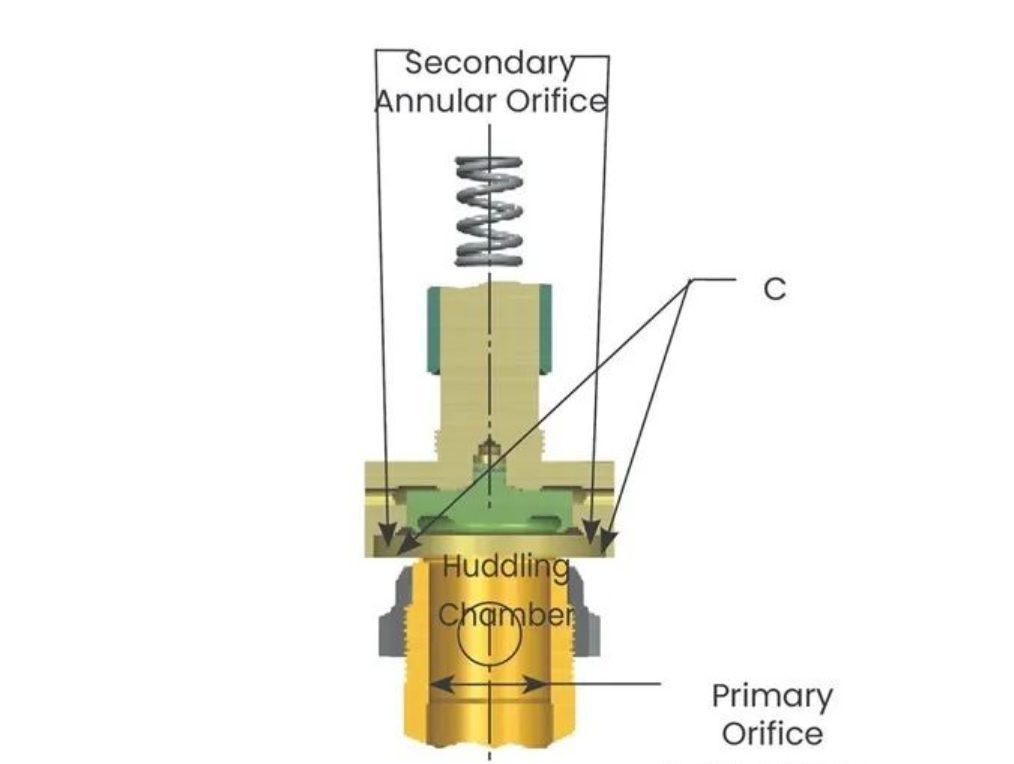

The operation of a pressure relief valve (PRV) is straightforward yet crucial for safety in various applications, particularly in pressure vessels and systems subject to fluctuations in inlet pressure. When the internal pressure of a system rises to a preset pressure, the valves open, allowing fluid (gas or liquid) to escape through the inlet and outlet ports.

This process effectively reduces the outlet pressure and provides essential overpressure protection. The valve design ensures that it can handle both high and low pressure conditions. If the pressure continues to rise, the valves may be forced open to relieve excess pressures, preventing potential system failure.

Typically, a spring acts against a diaphragm or piston to keep the valve closed under normal conditions. Once the internal pressure exceeds the set point, the valve opens, and fluid is discharged, ensuring the system can function properly. The valves will close automatically once the pressure returns to a safe level, preventing excessive flow and maintaining system integrity.

Types of Pressure Relief Valve

Pressure Relief Valves come in various types, each designed for specific applications and operating conditions. Common types include spring-loaded valves, which use a spring to control opening, and pilot-operated valves, which use a secondary valve for greater precision. Thermal relief valves are also available for temperature-related pressure relief. It is crucial to understand these types when you select the right valve for your system. The most common types are as below.

Spring-Loaded Relief Valves:

Utilize a spring mechanism to maintain the valve in a closed position until the set pressure is exceeded. When the pressure rises above the predetermined level, the spring compresses, allowing the valve to open and relieve excess pressure.

Pilot-Operated Relief Valves

Use a smaller pilot valve to control the larger main valve, allowing for more precise pressure control. The pilot valve responds to changes in system pressure, enabling the main valve to open or close based on demand.

Bursting Discs

A non-reclosing device that ruptures at a specific pressure to release fluid. These are often used in conjunction with PRVs for added safety, especially in applications requiring rapid pressure relief.

Safety Relief Valves

Designed for gas and vapor applications, these valves can also handle liquid flows, providing a safety mechanism to prevent overpressure conditions from sudden increases.

Vacuum Relief Valves

These valves are specifically designed to prevent vacuum conditions in a tank or system. When internal pressure drops below atmospheric pressure, the valve opens to allow air into the system, preventing collapse or damage.

Pressure Relief Valves In Operation

In operation, a pressure relief valve (PRV) typically remains closed until the upstream pressure reaches the predetermined set point. Once this set pressure is attained, the valve begins to open, allowing fluid to flow and relieving excess pressure. As the pressure increases, the valve continues to open further, permitting a greater flow of fluid.

When the upstream pressure falls a few psi below the set point, the valve automatically closes again, effectively stopping the flow. This cycle ensures that the system maintains safe pressure levels, preventing potential damage or failure due to overpressure.

Typical Application of Pressure Relief Valves

Pressure Relief Valves (PRVs) are essential components used across a variety of industries to protect systems from overpressure and potential equipment failure. They are designed to operate effectively in different environments, including both gas service and liquid service applications. PRVs are used in various applications, including:

-

- Water Heaters::

PRVs are essential in various applications, including pressure relief valve water heaters, where they help manage pressure and enhance safety by preventing overpressure conditions.

- Water Heaters::

-

- Boilers:

PRVs prevent overpressure in steam systems by venting excess steam to the atmosphere, ensuring safe operation.

- Boilers:

-

- Chemical Processing:

They protect reactors and storage tanks by controlling pressure and maintaining the integrity of critical seals.

- Chemical Processing:

-

- Oil and Gas:

PRVs ensure safety in pipelines and refineries by managing pressure fluctuations during fluid pumping.

- Oil and Gas:

-

- Water Treatment Plants:

These valves manage pressure to prevent overpressure conditions that could lead to system failures.

- Water Treatment Plants:

-

- HVAC Systems:

PRVs help control pressure in ductwork and equipment, ensuring efficient and safe operation.

- HVAC Systems:

Frequently Asked Questions

Why is my pressure relief valve leaking?

Leaking can occur due to several reasons, including a damaged seat, debris trapped in the valve, or a worn-out spring. Regular maintenance and inspection can help prevent leaks. Learn more about reasons and solutions for water heater pressure relief valve leaking.

What is the Pressure Relief Valve symbol?

Pressure relief valves frequently have a specific symbol in engineering diagrams that denotes their purpose and connection points.

What is the difference between a pressure relief valve and safety relief valves?

While both serve similar purposes, a pressure relief valve can handle both gases and liquids, whereas a pressure safety valve is typically designed for gas applications.

How to adjust the pressure relief valve?

To adjust a pressure relief valve (PRV), first ensure safety by wearing appropriate protective gear and depressurizing the system if needed. Locate the adjustment screw on the valve, then turn it clockwise to increase the set pressure or counterclockwise to decrease it. Make small adjustments, then re-pressurize the system and check the pressure gauge to confirm the new setting. Monitor the PRV to ensure it operates correctly at the adjusted pressure.

Why is my boiler safety relief valve leaking?

Excessive pressure, shoddy installation, or wear and tear can all lead to leaks in boiler safety relief valves. Regular inspection is essential to ensure safety and functionality.

Conclusion

Pressure relief valves (PRVs) are essential components in maintaining safety and operational integrity in pressurized systems. By understanding the basics of PRVs, including their function, types, and applications, you can make informed decisions regarding their selection and maintenance. It is also important to differentiate these valves from pressure safety valves, which are specifically designed for safety applications.

For high-quality pressure relief valves and related services, consider exploring the products offered by Amber. Visit Amber Valves to find the right solutions for your needs. By the way, if you have any questions about the pressure relief valve, please feel free to consult with our professional team.