Showing 1–9 of 10 results

Ball valves give you seamless control over fluid flow, designed to stand up to demanding applications with ease. Their reliable, leak-proof design means fewer worries and maintenance costs, while their quick-turn handles provide precise, effortless control in any setting. From residential plumbing to industrial systems, ball valves are crafted to offer durability, efficiency, and peace of mind wherever you need it. Enjoy smooth operation, easy installation, and the security of a valve that performs under pressure.

Filter by Materials

- Brass (1)

- Carbon Steel (4)

- CF8 (3)

- CF8M (3)

- FRPP (2)

- PVC-C (3)

- PVC-U (4)

- Stainless Steel (5)

- WCB (3)

Filter by Diameter

- DN100 - 4" inch (10)

- DN125 - 5" inch (6)

- DN15 - 1/2" inch (8)

- DN150 - 6" inch (6)

- DN20 - 3/4" inch (10)

- DN200 - 8" inch (5)

- DN25 - 1" inch (9)

- DN250 - 10" inch (3)

- DN32 - 1 1/4" inch (9)

- DN40 - 1 1/2" inch (9)

- DN50 - 2" inch (10)

- DN65 - 2 1/2" inch (10)

- DN80 - 3" inch (10)

Filter by

- Adhesive Connection (1)

- Butt Welding (4)

- Female Thread (2)

- Flange PN16 (5)

- Flange PN25 (5)

- Flange PN40 (5)

- Socket (4)

Different Types of Ball Valves

Top entry ball valves, side entry ball valves, floating ball valves and trunnion ball valves are four main industrial valves. Here’s an overview of different types of ball valves based on design and functionality:

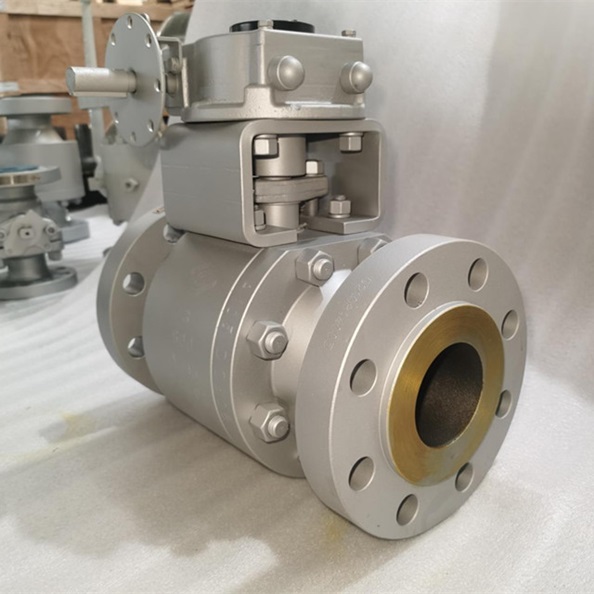

Top Entry Ball Valve

Top entry ball valves are designed with a one-piece body, allowing the ball, stem, and other internals to be accessed and maintained from the top. This design enables in-line maintenance, making it easy to inspect and replace parts without removing the valve from the pipeline.

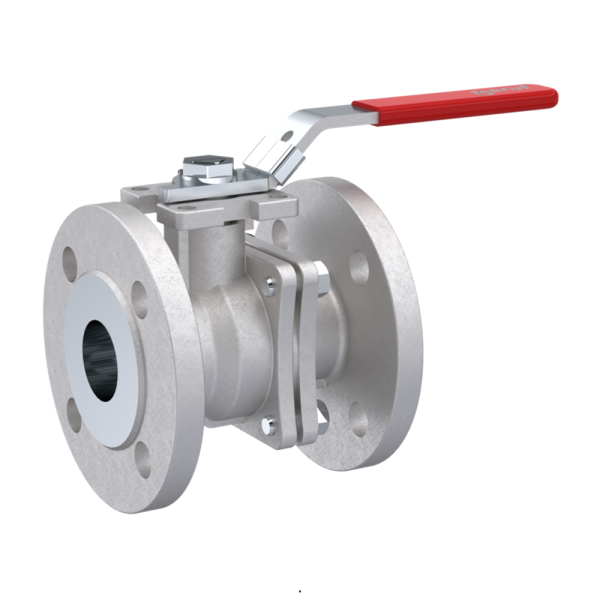

Side Entry Ball Valve

Side entry ball valves, also known as split body ball valves, consist of two or three pieces assembled horizontally. The ball is inserted from the side, which allows for easy assembly and disassembly in the field.

Floating Ball Valve

The ball in a floating ball valve is not fixed but held in place by two elastomeric seats, allowing it to move slightly. When pressure is applied, the ball presses against the downstream seat to form a tight seal.

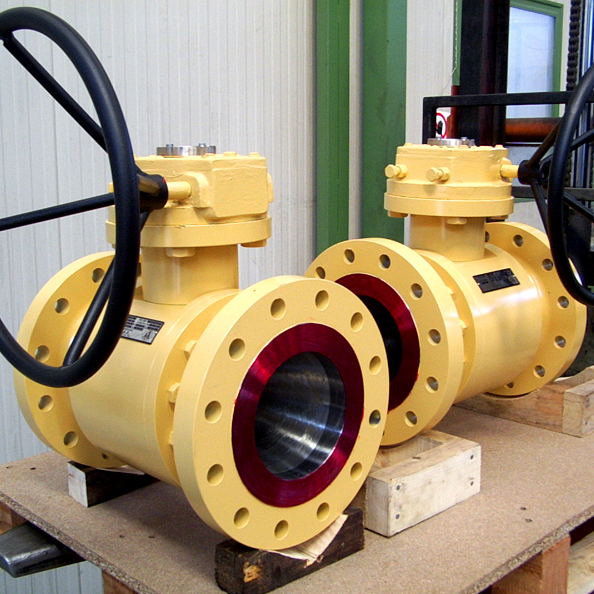

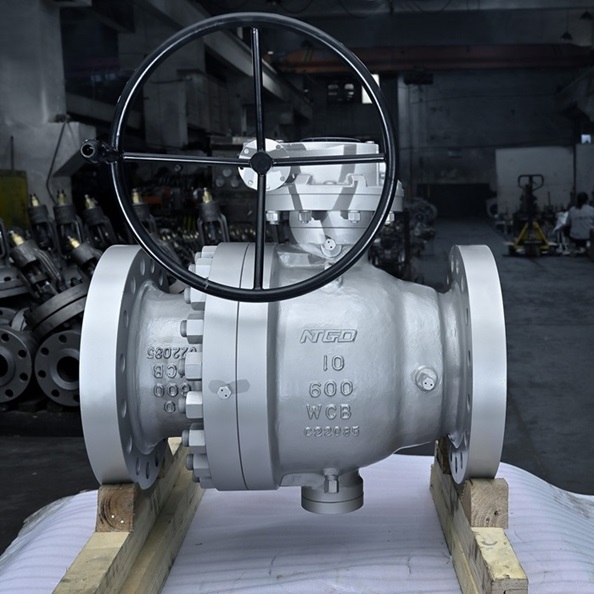

Trunnion Ball Valve

Trunnion ball valves have additional support in the form of a shaft, or trunnion, that anchors the ball at the top and bottom. This design reduces the torque required to operate the valve, making it easier to use in high-pressure situations.

Ball Valves VS Gate Valves

What are the differences between ball valves and gate valves?

Ball valves and gate valves are both essential components in flow control systems, but they serve different purposes and are suited to different applications. Both types of valves are designed to control fluid flow through a pipeline, yet they operate on different mechanisms and have unique strengths. Choosing between them depends on the specific requirements of a system, such as the need for quick shut-off, precise flow control, or durability under high pressure.

Ball valves use a rotating spherical ball with a hole through its center, allowing fluid to pass through when aligned with the pipe. With a simple quarter-turn, ball valves open or close instantly, making them ideal for applications that require rapid shut-off, such as emergency systems. Gate valves, on the other hand, operate by raising or lowering a flat or wedge-shaped gate to start or stop flow. This slower, multi-turn operation is better suited for applications where gradual flow control is desired and where the valve will stay open or closed for extended periods.

Ultimately, ball valves excel in providing fast, reliable shut-off and leak-proof performance, while gate valves offer better control for larger-scale systems that require more gradual adjustments. Both have their places in plumbing, oil and gas, and industrial applications, with the choice largely dictated by the operational and environmental demands of the specific application.

FAQs for Ball Valves

A ball valve is used to control the flow of liquids, gases, or slurries in a pipeline. With a simple 90-degree turn of the handle, a ball valve can start, stop, or regulate flow, making it ideal for quick shut-off applications. It provides a reliable, leak-proof seal and is commonly used in various industries, including oil and gas, water treatment, chemical processing, and HVAC systems.

A ball valve differs from other "regular" or traditional valves, such as gate or globe valves, in its design and operation. Ball valves use a rotating spherical ball with a hole through the center, allowing quick on/off control with a quarter turn. Regular valves, like gate valves, generally require multiple turns to open or close, providing slower, more gradual flow control. Ball valves are typically preferred for applications needing quick shut-off and a tight seal, while regular valves often suit systems requiring finer control over flow.

Common problems with ball valves include wear and tear on the seats, which can lead to leaks over time, especially if the valve is frequently operated in high-pressure environments. Additionally, debris can accumulate within the valve, causing blockages or preventing a full seal. In freezing conditions, trapped fluid inside the valve can expand and cause cracking or damage to the valve components. Routine maintenance and inspections can help prevent these issues.

Disadvantages of ball valves include limited suitability for throttling applications, as partially open positions may cause vibration and wear on the seats. They can also be more expensive than simpler valve types, such as gate or check valves, especially for larger sizes. Ball valves may also struggle with extreme temperatures, as the sealing material can degrade, leading to leaks. Finally, ball valves require more lateral space for the handle's quarter-turn operation, which can be a constraint in compact installations.